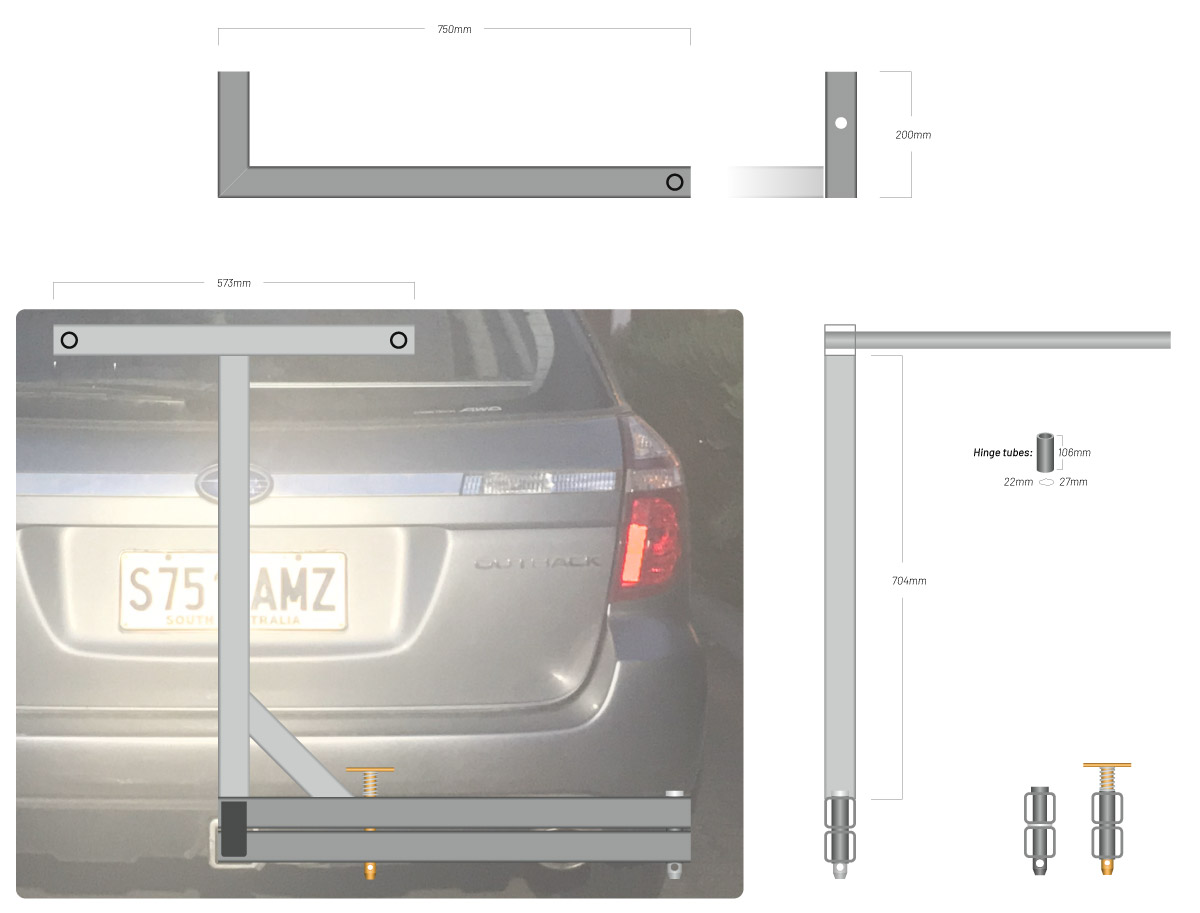

Measuring up the back of my 2007 Subaru Outback to determine the best geometry for the carrier.

I brought photos and measurements into Illustrator at 100% scale to plan things down to the millimeter. The diagonal support proved unneeded.

The hinge pin came to me as if by magic. Exactly the right size, found just lying in the gutter on Glynburn Road.

My cheap (free) step drills did an admirable job but proved to be the wrong choice for the larger holes.

Step drills are amazing for softer materials and even thin steel. This was not thin steel.

50mm x 50mm x 4mm steel tube was used for the hitch, lower arm and swing arm. Here a deep fillet is cut to allow better weld penetration. Flux-core MIG, if you were curious.

Bimetal holesaws are pricey but worth every cent. This is what I should have done from the start.

Testing the tacked-together frame prior to final welding.

The tynes are welded in a through-hole fashion for added strength and rigidity.

Priming prior to painting in the final satin black enamel.

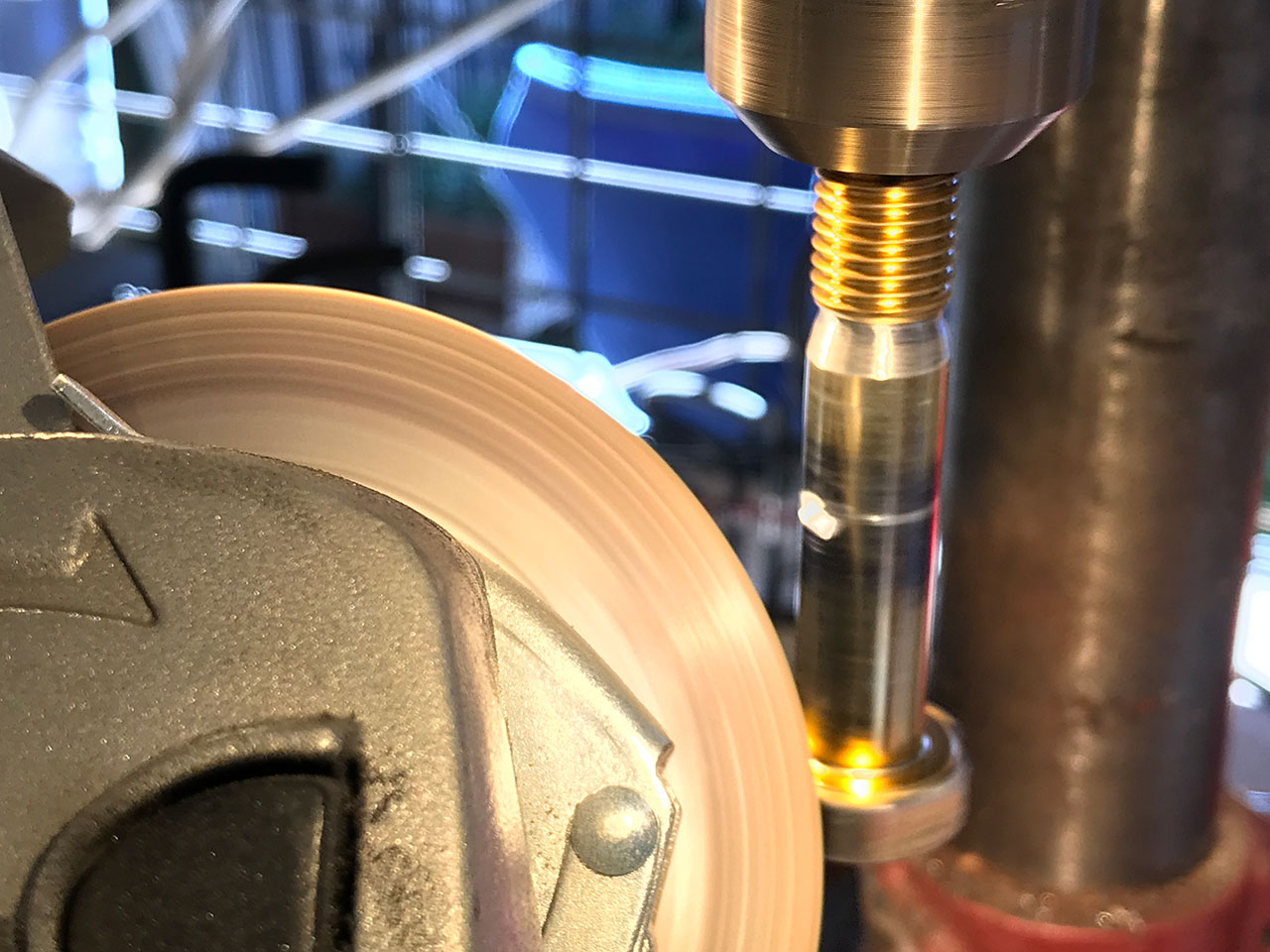

I don't have a lathe (yet) so got creative when the need arose to machine an M12 cross-bolt for the main hinge.

The main hinge pin with its ancillary hardware.

To protect the bike frames, the carrier was skinned in marine carpet and used bike inner tubes.

To protect the bike frames, the carrier was skinned in marine carpet and used bike inner tubes.

The completed bike carrier fitted with the regular rego plate from the back door of the car.

The first test run revealed a very small amount of rattling, later remedied with a pad of Sugru on the lower arm.

The completed bike carrier, packed and ready to go.

With the removal of a Treg type lynch pin, the carrier and bikes can be swung out of the way to access the rear door.

One of the main reasons we hadn’t taken our bikes away camping before has been the difficulty of transporting them. We pack an astounding amount into and onto my 2007 Subaru Outback even without them.

Adding a bike carrier to the tow hitch was always an option but would have sacrificed ease of access to the rear of the vehicle. Given this is where the fire extinguisher and esky live, that was never going to be an option.

Having already designed and built a swing-away tyre carrier for the Landy I thought, ‘…why not make a swing-away bike carrier?’. This isn’t a new invention by any means but making my own offered the benefit of making it exactly the right size for my car.

Then end result is a sturdy, convenient way to transport up to 4 bikes while retaining rear accessibility. The carrier swings away to the driver’s side in seconds, allowing for safe esky entrance while parked at the side of the road.